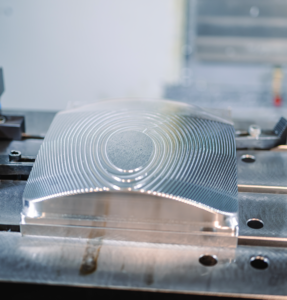

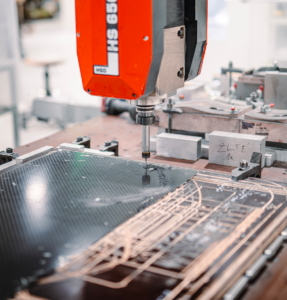

Our workflow encompasses the entire spectrum, starting from the inception of the idea to the completion of the 3D design, with the aid of advanced creation and simulation software employed for both the end product and manufacturing tools. We are licensed with Solidworks and SolidCAM. Fine-tuning the settings of the machining centers to optimize processing times and achieve the precise tolerances required.

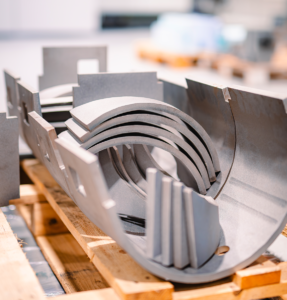

CNC machines are critical in transforming 3D models into precise, high-quality physical components. CNCs achieve exceptional accuracy, repeatability, and efficiency across a wide range of materials. They follow detailed specifications from 3D models, ensuring seamless integration between design and manufacturing. This precision and reliability make CNC technology indispensable in modern production workflows, from prototyping to large-scale manufacturing.

- HAAS UMC 750 SS

- 5 axis

- 0.76 x 0.5 x 0.5m (X, Y, Z)

- 12.000rpm and 22,4 KW

- HAAS VF-2SSYT-EU

- 3 axis

- 0.7 x 0.5 x 0.5m (X, Y, Z)

- 12.000rpm

- SAHOS Dymanic

- 5 axis

- 2.8 x 1.2 x 0.7m (X, Y, Z)

- 22.000rpm and 9 KW

- BRETON HAWX E1

- 5 axis

- 4 x 1.9 x 1.3m (X, Y, Z)

- 24.000rpm and 26 KW

- HAAS ST-20Y

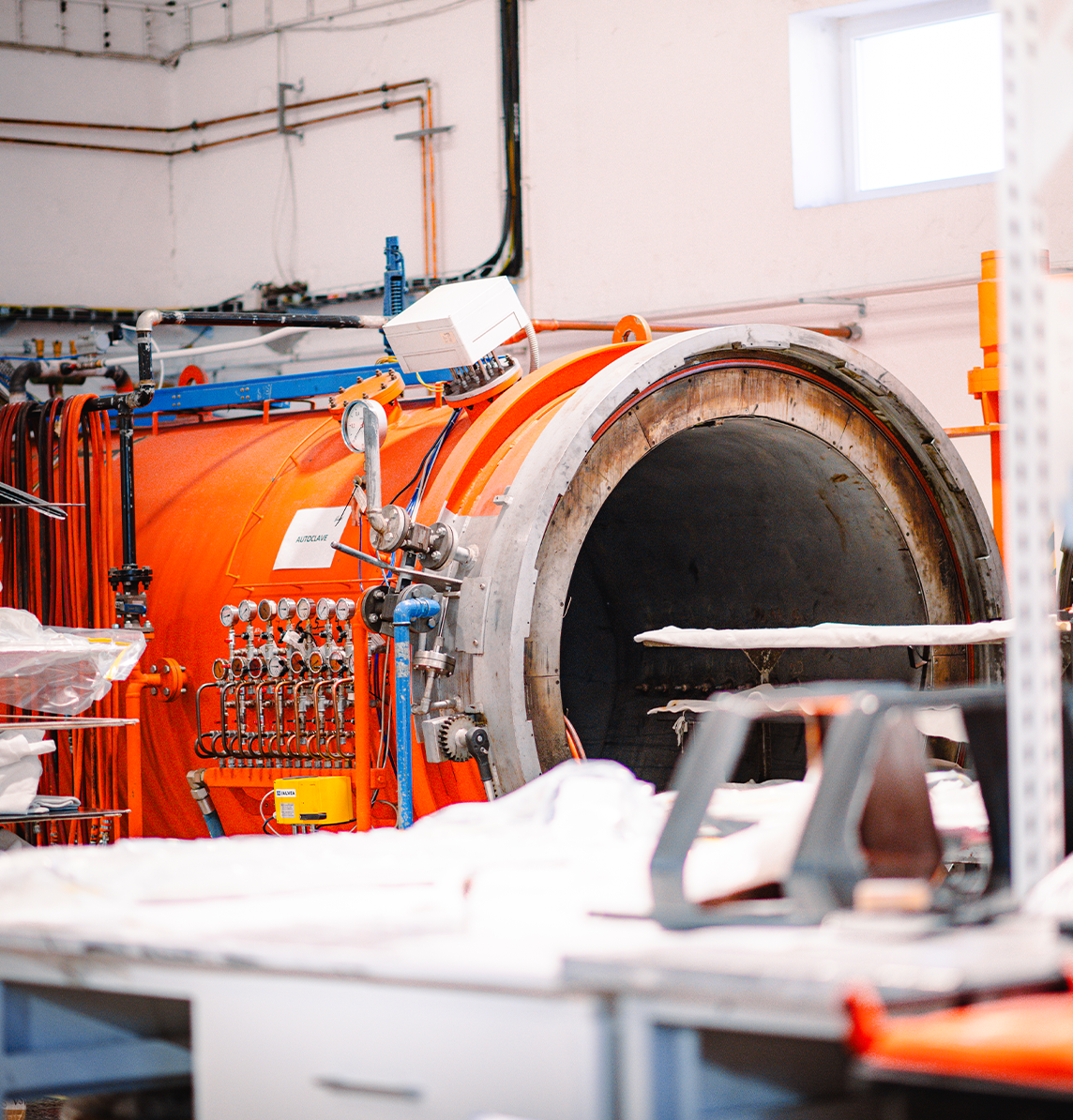

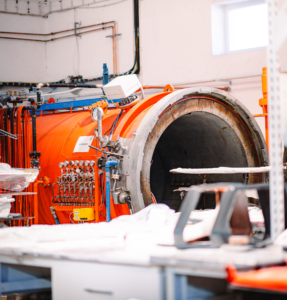

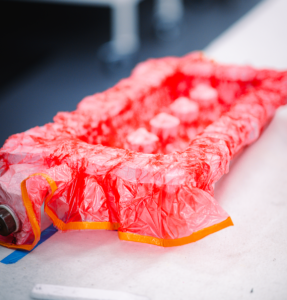

Laminating prepreg materials is a key step in composite manufacturing, where layers of resin-impregnated fibers are arranged to meet specific strength and performance needs. The process involves precise layer alignment using vacuum and autoclave techniques to ensure compaction and eliminate defects. This results in lightweight, durable components ideal for aerospace, automotive, and other high-performance applications. As part of our dedicatication to perfection, we created a special room with temperature, pressure and humidity control for this process.

Autoclave and oven curing are essential processes in composite manufacturing to solidify and strengthen materials. Autoclave curing uses high pressure and temperature to compact laminates, remove voids, and ensure uniform resin distribution, producing superior-quality components for critical applications.

- Composite:

- Sanding

- Polishing

- Painting (outsourced)

- Bonding

- Assembly

- Metal

- Sanding

- Polishing

- Coating (outsourced)

Manufacturing quality is defined by strict adherence to established specifications. The costs associated with poor manufacturing quality can be substantial, which is why we are committed to producing high-quality products accurately and punctually on the first attempt, and consistently thereafter. This commitment enables us to achieve and sustain a competitive position in the global marketplace.